You've probably heard the saying "if it ain't broke, don't fix it." Well, in the construction industry, that kind of thinking will get you left behind. The most successful tradies and construction companies are constantly looking for ways to do things better, faster, and smarter.

Enter Kaizen - a Japanese approach to continuous improvement that's been revolutionising industries worldwide. The Lean Construction Institute reports that teams maintaining a mindset of continuous improvement are essential for thriving in a lean system.

Before you roll your eyes and think this is some corporate nonsense, hear us out. This isn't about fancy consultants or complicated systems. It's about getting better at what you do, one small step at a time.

What Is Kaizen? (And Why Should You Care?)

Kaizen literally means "change for better" in Japanese. It's not about massive overhauls or revolutionary changes. Instead, it's about making small, manageable improvements consistently over time.

Think about it this way: if you improved your efficiency by just 1% every day, by the end of the year you'd be 37 times better. That's the power of continuous improvement.

The Reality for Tradies

Research shows there's massive waste in construction:

- Working time on non-value adding activities can be up to 60% of total time

- Quality costs due to non-conformance can be up to 12% of total project costs

- Poor materials management can cost 10-12% of total project costs

- Excess material consumption averages 10% of total costs

That's a lot of wasted time and money. Kaizen helps you identify and eliminate these wastes, putting more money in your pocket and giving you back time in your day.

The 5-Step Kaizen Cycle (That Actually Works for Tradies)

The beauty of Kaizen is its simplicity. You follow a five-step cycle that you can apply to anything - from how you organise your tools to how you manage client communications.

Step 1: Identify Opportunities

Start by looking at your daily operations with fresh eyes. Where do you waste time? What frustrates you most? What makes jobs take longer than they should?

Common areas tradies identify:

- Tool organisation: Spending ages looking for the right tool

- Material handling: Multiple trips to the truck for supplies

- Communication gaps: Waiting for client decisions or clarifications

- Rework: Having to fix things that weren't done right the first time

- Travel time: Inefficient routes between jobs

- Admin tasks: Invoicing, quoting, scheduling taking forever

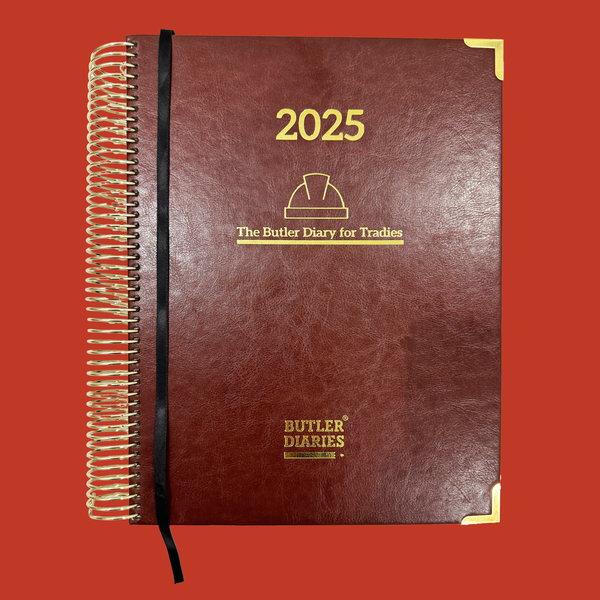

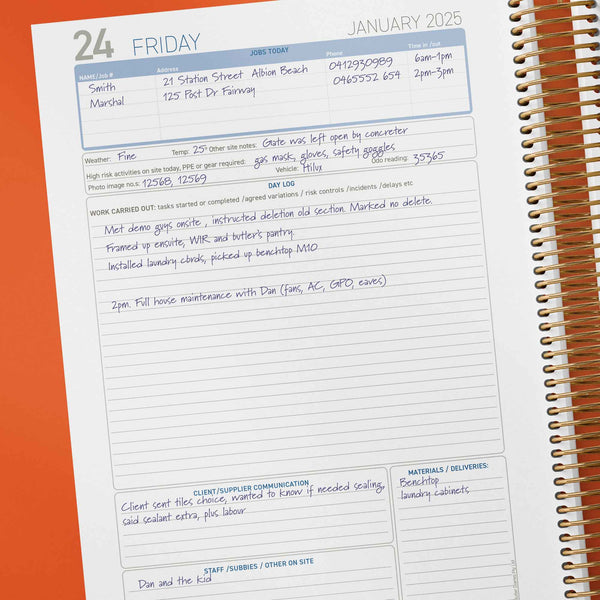

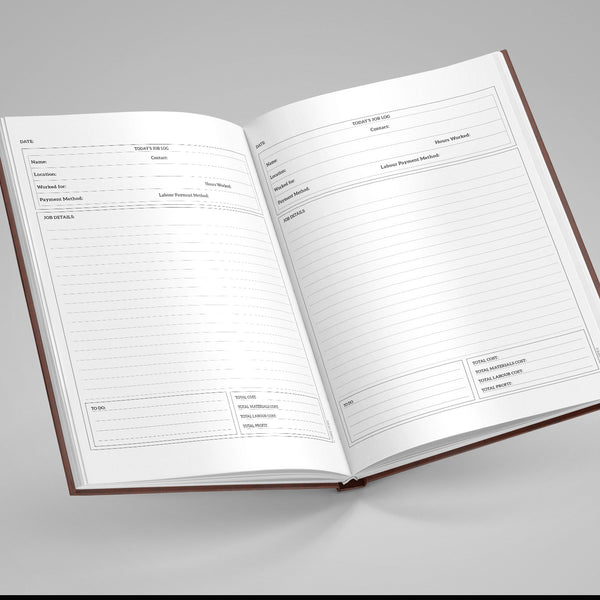

Your Construction Diary is perfect for this. Track your daily activities for a week and you'll quickly spot patterns and time-wasters.

Step 2: Plan Your Improvement

Once you've identified a problem, create a simple plan to address it. Don't try to fix everything at once - pick one thing and focus on that.

Example: Tool Organisation Problem

- Current state: Spend 15 minutes per day looking for tools

- Goal: Reduce search time to under 5 minutes

- Plan: Create designated spots for each tool, label everything, implement "clean as you go" system

- Timeline: Implement over next week

- Measure: Track time spent looking for tools

Step 3: Implement Changes

Put your plan into action. Start small and be consistent. The key is to actually do something, not just think about it.

Using our tool organisation example:

- Day 1: Organise one section of your toolkit

- Day 2: Label everything in that section

- Day 3: Practice putting tools back immediately after use

- Day 4-7: Expand to other sections

Document what you're doing in your Daily Log. This helps you stay accountable and track your progress.

Step 4: Measure and Evaluate

After a week or two, honestly assess the results. Did your change work? Are you actually saving time? What worked well and what didn't?

Key questions to ask:

- Am I achieving my original goal?

- What unexpected benefits or problems have appeared?

- Is this change sustainable long-term?

- What would I do differently next time?

- How can I build on this success?

Use your weekend review pages to reflect on these questions. Be honest - if something isn't working, that's valuable information too.

Step 5: Standardise and Repeat

If your improvement worked, make it your new standard way of doing things. If it didn't work, adjust and try again. Then move on to the next opportunity for improvement.

The goal isn't perfection - it's progress. Even failed experiments teach you something useful.

Real-World Kaizen Examples for Tradies

Here are some practical examples of how tradies are using Kaizen to improve their operations:

Example 1: The Efficient Electrician

Problem: Spending too much time on paperwork and quotes

Solution: Created standard templates and checklists

Result: Reduced quote preparation time by 40%, more time for actual work

Example 2: The Organised Plumber

Problem: Constantly running back to truck for parts

Solution: Developed job-specific kit lists and pre-loaded bags

Result: Cut material retrieval trips by 60%, faster job completion

Example 3: The Smart Carpenter

Problem: Rework due to measurement errors

Solution: Implemented "measure twice, cut once" checklist system

Result: Reduced material waste by 25%, improved profit margins

Example 4: The Strategic Builder

Problem: Poor communication causing delays

Solution: Daily photo updates and brief client check-ins

Result: Eliminated 80% of communication-related delays

The 8 Types of Waste to Watch For

Kaizen focuses on eliminating waste (called "muda" in Japanese). Here are the eight types of waste that cost tradies time and money:

- Defects: Rework, fixes, warranty calls

- Overproduction: Doing more than the client asked for

- Waiting: Delays, approvals, material deliveries

- Non-utilised talent: Not using team members' full skills

- Transportation: Unnecessary movement of materials or tools

- Inventory: Too much stock, outdated materials

- Motion: Unnecessary movement by workers

- Extra processing: Doing more work than necessary

Start by identifying which of these wastes affects you most, then use the Kaizen cycle to address them one by one.

How Your Construction Diary Supports Kaizen

The Construction Diary isn't just for scheduling - it's your Kaizen companion. Here's how:

Daily Planning and Reflection

Use your diary to plan improvements and reflect on results. The daily structure helps you stay focused on continuous improvement goals.

Problem Identification

Track recurring issues, delays, and frustrations. Patterns become obvious when you write them down consistently.

Progress Monitoring

Document what you're trying to improve and measure your progress. Small wins become visible and motivating.

Knowledge Capture

Record what works and what doesn't. Your diary becomes a personal manual of best practices.

Client Communication

Better documentation leads to clearer communication, fewer misunderstandings, and more satisfied clients.

The Daily Log provides even more space for detailed improvement tracking and analysis.

Getting Started: Your First Kaizen Project

Ready to give this a try? Here's a simple way to start:

Week 1: Observe and Record

- Use your diary to track daily activities and time spent

- Note frustrations, delays, and inefficiencies

- Don't try to fix anything yet - just observe

Week 2: Identify and Plan

- Review your notes and identify the biggest time-waster

- Choose ONE thing to improve

- Create a simple plan with specific, measurable goals

Week 3: Implement

- Put your plan into action

- Track your progress daily

- Adjust if something isn't working

Week 4: Evaluate

- Measure your results

- Decide what to keep, change, or abandon

- Plan your next improvement

Common Mistakes to Avoid

- Trying to fix everything at once: Start small and build momentum

- Not measuring results: How do you know if it's working if you don't track it?

- Giving up too quickly: Some improvements take time to show results

- Making it too complicated: Simple solutions often work best

- Ignoring team input: Your apprentice or crew might have great ideas

- Stopping after one cycle: Continuous improvement means never stopping

The Compound Effect of Small Improvements

Here's what makes Kaizen so powerful: small improvements compound over time. Consider this:

- Save 10 minutes per day = 40+ hours per year

- Reduce material waste by 5% = Hundreds or thousands in savings annually

- Improve first-time quality by 10% = Massive reduction in callbacks and rework

- Better client communication = More referrals and repeat business

These aren't massive changes, but they add up to significant improvements in your bottom line and quality of life.

Building a Culture of Improvement

If you've got a team, get them involved. Kaizen emphasises that continuous improvement involves everyone, from top management to front lines.

Team Kaizen Ideas

- Weekly improvement meetings: 15 minutes to discuss what's working and what isn't

- Suggestion systems: Let team members propose improvements

- Shared learning: When someone finds a better way, share it with everyone

- Celebrate small wins: Recognise and reward improvements

- Lead by example: Show that you're committed to getting better

Technology and Kaizen

Modern construction is embracing technology to support continuous improvement. BIM (Building Information Modeling) generates data that enables teams to identify trends, predict issues, and optimise workflows.

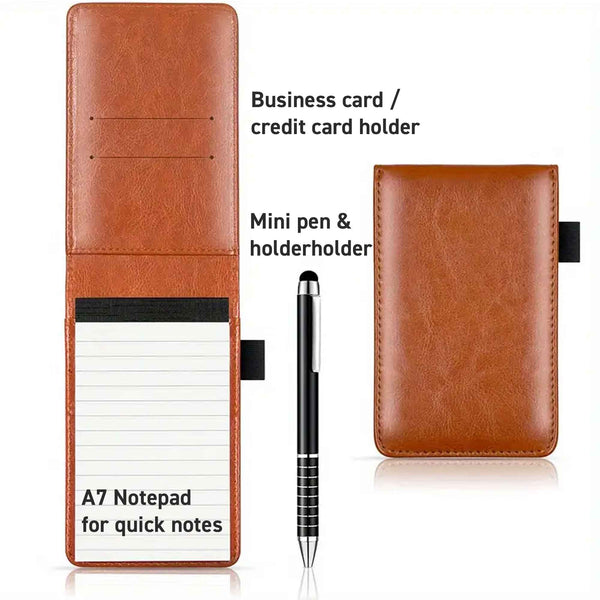

But you don't need expensive software. Your Construction Diary, combined with simple tools like:

- Phone camera for before/after photos

- Voice memos for quick notes

- Simple spreadsheets for tracking metrics

- Basic project management apps

Can support your continuous improvement efforts effectively.

The Bottom Line

Kaizen isn't about perfection - it's about progress. It's about looking at your work with fresh eyes and asking, "How can I do this better?"

The construction industry faces increasing pressure to be more efficient, more sustainable, and more profitable. In this dynamic environment, a commitment to continuous improvement isn't just a nice idea; it's a necessity.

The tradies and companies that embrace continuous improvement will be the ones that thrive. They'll work smarter, not just harder. They'll waste less time and materials. They'll build better relationships with clients. They'll make more money and have more time for the things that matter.

Your Kaizen Journey Starts Now

Don't wait for the perfect moment or the perfect plan. Start small, start today. Pick one thing that frustrates you about your work and commit to making it better over the next month.

Use your Construction Diary to document your journey. Track your experiments, measure your results, and build on your successes.

Remember: the goal isn't to revolutionise your entire operation overnight. It's to get a little bit better every day. That's the power of Kaizen, and that's how smart tradies stay ahead of the competition.

Ready to start your continuous improvement journey? Get your Construction Diary and begin documenting your path to excellence. Small changes, big results.