The Phone Call That Nearly Ended Dave's 12-Year Plumbing Business

It started like any other Tuesday morning. Dave Wilson was having his usual coffee when the phone rang. "This is WorkSafe. We'll be conducting a compliance audit of your business next week. Please have all safety documentation ready for review."

Dave's stomach dropped. Like most small contractors, he'd been putting off the "paperwork side" of safety compliance. Sure, he ran a safe operation - no major incidents in 12 years. But proper documentation? That was something he'd get to "when things slowed down."

Seven days later, WorkSafe walked away with a $25,000 fine that forced Dave to nearly close his business. He had to refinance his house to pay it. The tragic part? Every safety measure was in place. He just couldn't prove it.

The WorkSafe Reality Every Tradie Needs to Understand

Here's what most tradies don't realise about WorkSafe compliance: it's not enough to be safe. You have to prove you're safe. And that proof needs to be documented, systematic, and readily available for inspection.

According to Safe Work Australia data, 40% of audited businesses receive penalties, with average fines of $25,000. But here's the kicker - most violations aren't for actual safety breaches. They're for inadequate documentation.

In my 15 years managing construction sites with zero major incidents, I've learned that successful safety management is 50% doing the right things and 50% proving you did them.

What WorkSafe Actually Looks For

When WorkSafe auditors arrive, they're not just checking if your tradies are wearing hard hats. They want evidence of systematic safety management:

Daily Safety Documentation: Evidence that safety checks happen every day, not just when inspectors visit.

Incident Recording: Complete records of every incident, no matter how minor, including corrective actions taken.

Training Records: Proof that every worker has received appropriate safety training and understands site-specific risks.

Risk Assessment Documentation: Written evidence that you've identified potential hazards and implemented controls.

Equipment Inspection Logs: Regular safety checks of tools, machinery, and safety equipment with documented results.

The Five Documentation Mistakes That Destroy Businesses

After reviewing hundreds of WorkSafe cases, I've identified the five documentation failures that consistently result in major penalties:

1. The "Mental Note" Safety System

You do your safety checks every morning, but you don't write them down. You know which equipment needs attention, but there's no paper trail. This approach is business suicide during an audit.

WorkSafe doesn't care what you remember doing. They care what you can prove you did.

2. Incomplete Incident Reporting

A tradie cuts their finger on Tuesday. You treat it, tell them to be more careful, and move on. No written report, no analysis of what went wrong, no documented corrective action.

Six months later, WorkSafe asks for your incident records. That "minor" cut becomes evidence of inadequate safety management.

3. Missing Training Documentation

Your crew knows how to work safely - you've taught them well. But when WorkSafe asks for training records, you've got nothing to show them.

Verbal training doesn't count. If it's not documented, it didn't happen in WorkSafe's eyes.

4. Reactive Safety Management

You address safety issues as they come up, but you don't document your proactive safety measures. WorkSafe wants to see evidence of systematic risk management, not just crisis response.

5. Scattered Documentation

Your safety records are everywhere - some on your phone, some on scraps of paper, some in your head. When WorkSafe wants comprehensive documentation, you can't produce it quickly or completely.

The Documentation System That Passes Every Audit

After managing 200+ projects with zero major incidents and multiple successful WorkSafe inspections, here's the documentation system that protects your business:

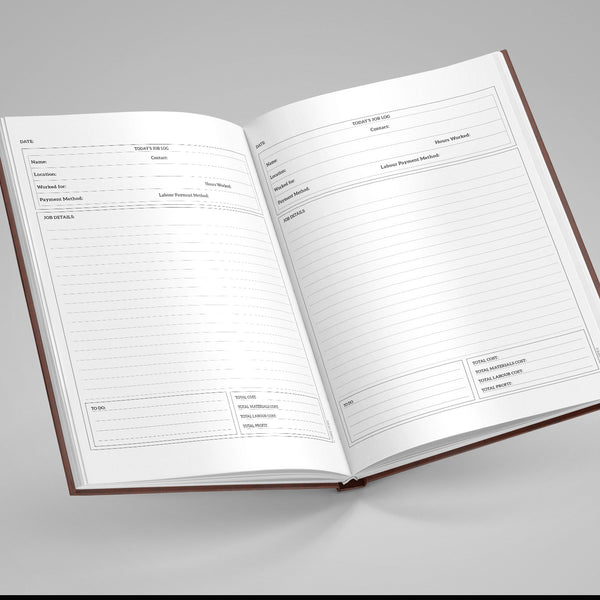

Daily Safety Prestart Documentation

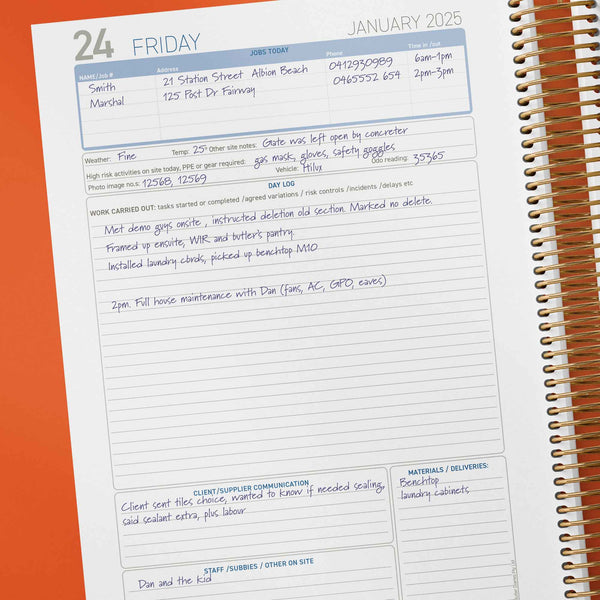

Start every day with documented safety checks in the Construction Diary's "High risk activities on site today, PPE or gear required" section. Weather conditions, site hazards, equipment status, crew safety briefings - everything recorded in real-time.

This dedicated section makes systematic safety documentation automatic. You've got structured space for every check, plus room for notes about changing conditions or emerging risks.

Comprehensive Day Log Safety Records

The Construction Diary's "Work Carried Out" section includes space for documenting "risk controls/incidents/delays" alongside daily activities. Every incident gets recorded immediately with what happened, why it happened, what you did about it, and prevention measures.

This integrated approach shows WorkSafe that safety management is part of your daily operations, not an afterthought.

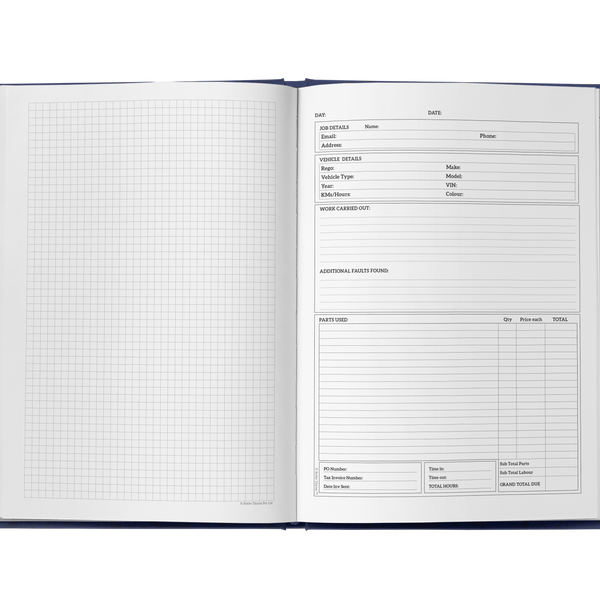

Staff and Site Documentation

Use the "Staff/Subbies/Other on Site" section to document who received safety briefings, training updates, and competency verification. Include dates and specific safety topics covered.

The "Other site notes" field captures changing site conditions, new hazards identified, and safety measures implemented throughout the day.

Equipment and Vehicle Safety Tracking

The Construction Diary's vehicle tracking section includes odometer readings and equipment condition notes. Document equipment inspections, maintenance schedules, and safety equipment checks here.

This creates a comprehensive safety timeline that shows systematic equipment management.

Client Communication Safety Records

Use the "Client/Supplier Communication" section to document safety discussions with customers, safety requirement changes, and hazard notifications. This proves you're managing safety communication professionally.

Why Physical Documentation Protects You Better Than Digital

I know digital tools seem more efficient, but here's why successful contractors still rely on physical documentation for WorkSafe compliance:

Immediate Accessibility: No password issues, no app crashes, no connectivity problems when WorkSafe wants to see records instantly.

Legal Credibility: Handwritten, dated records carry more weight in legal proceedings. They're harder to modify and show authentic, real-time documentation.

Complete Accountability: Physical signatures and handwriting create personal accountability that digital entries often lack.

Historical Overview: You can spread weeks of records across a table, letting auditors see patterns and consistency at a glance.

The True Cost of Poor Safety Documentation

The penalties for inadequate WorkSafe documentation go far beyond fines:

- Direct Penalties: Fines ranging from $5,000 to $1.5 million depending on the severity

- Business Disruption: Work stoppages while compliance issues are addressed

- Insurance Complications: Higher premiums or policy cancellations

- Reputation Damage: Public safety violations affect client confidence

- Legal Liability: Poor documentation weakens your position in injury claims

Compare this to the cost of proper documentation: about 15 minutes per day to protect your entire business.

What WorkSafe Compliance Actually Looks Like

Professional WorkSafe compliance isn't about perfect safety records - it's about systematic documentation that proves your commitment to continuous improvement.

The Construction Diary includes everything WorkSafe auditors want to see:

- Daily safety prestart sections for systematic hazard identification

- Integrated incident reporting within daily work logs

- Staff safety training records in daily attendance tracking

- Equipment inspection documentation through vehicle and site logging

- Safety communication records in client interaction sections

This isn't just paperwork - it's business insurance. Every contractor I know who's survived WorkSafe audits uses systematic safety documentation that's integrated into their daily operations.

Start Building Audit-Proof Documentation Today

You can't afford to gamble with WorkSafe compliance. Every day without proper safety documentation is a day your business is at risk.

The contractors who sleep soundly aren't the luckiest - they're the ones who can prove they're doing everything right.

Don't wait for the phone call that could end your business. Start documenting your safety management professionally today.

Your business depends on it.